A southern US utility was forced to derate from 770 MW to 700 MW due to opacity excursions during the summer heat wave. The ESP had originally been designed for fly ash from local medium to high sulfur coal. Because of SO2 emission regulations, a switch was made to lower sulfur coal. An SO3 system was installed to condition the fly ash.

EPSCO was retained by the utility to study the problem and to recommend actions which would regain all or part of the lost generation due to the derate. |

A southern US utility was forced to derate from 770 MW to 700 MW due to opacity excursions during the summer heat wave. The ESP had originally been designed for fly ash from local medium to high sulfur coal. Because of SO2 emission regulations, a switch was made to lower sulfur coal. An SO3 system was installed to condition the fly ash.

EPSCO was retained by the utility to study the problem and to recommend actions which would regain all or part of the lost generation due to the derate. |

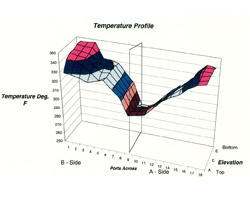

After discussions with the utility, it was decided to use zone cooling. This technique carefully adds highly atomized water droplets to the highest temperature zones of the flue gas. Zone cooling differs from humidification, which treats the entire flue gas stream.

|

A temporary system was installed to prove the concept of zone cooling, while a permanent system was designed. |